Page 10 - Hub 4 Magazine issue 53

P. 10

Cover Story

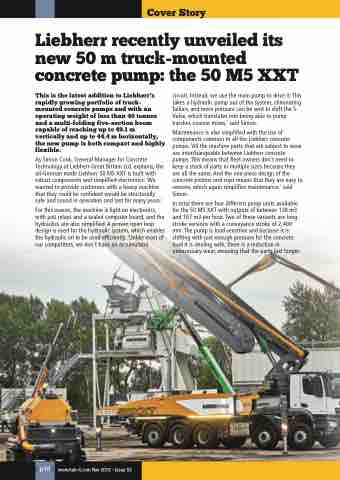

Liebherr recently unveiled its new 50 m truck-mounted concrete pump: the 50 M5 XXT

This is the latest addition to Liebherr’s rapidly growing portfolio of truck- mounted concrete pumps and with an operating weight of less than 40 tonnes and a multi-folding five-section boom capable of reaching up to 49.1 m vertically and up to 44.4 m horizontally, the new pump is both compact and highly flexible.

As Simon Cook, General Manager for Concrete Technology at Liebherr-Great Britain Ltd, explains, the all-German made Liebherr 50 M5 XXT is built with robust components and simplified electronics: ‘We wanted to provide customers with a heavy machine that they could be confident would be structurally safe and sound in operation and last for many years.’

For this reason, the machine is light on electronics, with just relays and a sealed computer board, and the hydraulics are also simplified. A proven open loop design is used for the hydraulic system, which enables the hydraulic oil to be used efficiently. ‘Unlike most of our competitors, we don’t have an accumulator

circuit. Instead, we use the main pump to drive it. This takes a hydraulic pump out of the system, eliminating failure, and more pressure can be sent to shift the S- Valve, which translates into being able to pump harsher, coarser mixes,’ said Simon.

Maintenance is also simplified with the use of components common to all the Liebherr concrete pumps. ‘All the machine parts that are subject to wear are interchangeable between Liebherr concrete pumps. This means that fleet owners don’t need to keep a stock of parts in multiple sizes because they are all the same. And the one-piece design of the concrete pistons and cups means that they are easy to remove, which again simplifies maintenance,’ said Simon.

In total there are four different pump units available for the 50 M5 XXT with outputs of between 138 m3 and 167 m3 per hour. Two of these variants are long- stroke versions with a conveyance stroke of 2,400 mm. The pump is load sensitive and because it is shifting with just enough pressure for the concrete load it is dealing with, there is a reduction in unnecessary wear, meaning that the parts last longer.

| p10 |

www.hub-4.com Nov 2018 - Issue 53