Page 31 - HUB-4 Magazine Issue 86

P. 31

Hillhead 2024

Preview

Why use concrete blocks for building storage bays

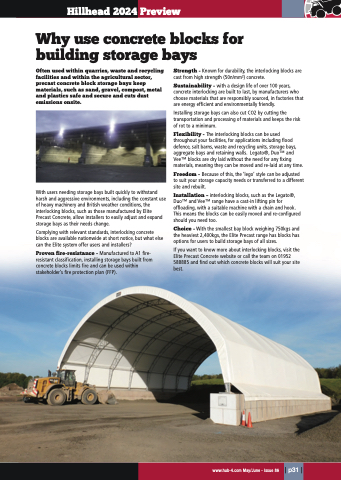

Often used within quarries, waste and recycling facilities and within the agricultural sector, precast concrete block storage bays keep materials, such as sand, gravel, compost, metal and plastics safe and secure and cuts dust emissions onsite.

Strength - Known for durability, the interlocking blocks are cast from high strength (50n/mm2) concrete.

Sustainability - with a design life of over 100 years, concrete interlocking are built to last, by manufacturers who choose materials that are responsibly sourced, in factories that are energy efficient and environmentally friendly.

Installing storage bays can also cut CO2 by cutting the transportation and processing of materials and keeps the risk of rot to a minimum.

Flexibility - The interlocking blocks can be used throughout your facilities, for applications including flood defence, salt barns, waste and recycling units, storage bays, aggregate bays and retaining walls. Legato®, DuoTM and VeeTM blocks are dry laid without the need for any fixing materials, meaning they can be moved and re-laid at any time.

Freedom - Because of this, the ‘lego’ style can be adjusted to suit your storage capacity needs or transferred to a different site and rebuilt.

Installation – interlocking blocks, such as the Legato®, DuoTM and VeeTM range have a cast-in lifting pin for offloading, with a suitable machine with a chain and hook. This means the blocks can be easily moved and re-configured should you need too.

Choice - With the smallest bay block weighing 750kgs and the heaviest 2,400kgs, the Elite Precast range has blocks has options for users to build storage bays of all sizes.

If you want to know more about interlocking blocks, visit the Elite Precast Concrete website or call the team on 01952 588885 and find out which concrete blocks will suit your site best.

With users needing storage bays built quickly to withstand harsh and aggressive environments, including the constant use of heavy machinery and British weather conditions, the interlocking blocks, such as those manufactured by Elite Precast Concrete, allow installers to easily adjust and expand storage bays as their needs change.

Complying with relevant standards, interlocking concrete blocks are available nationwide at short notice, but what else can the Elite system offer users and installers?

Proven fire-resistance - Manufactured to A1 fire- resistant classification, installing storage bays built from concrete blocks limits fire and can be used within stakeholder’s fire protection plan (FFP).

www.hub-4.com May/June - Issue 86

| p31 |