Customer Service Excellence for 22 years.

Celebrating 22 years of service excellence Harpscreen GB go from strength to strength playing an integral role in the transformation of the sector as the largest manufacturer of media for screening and recycling consumables.

Before Harpscreen came along in its current form quarry, plant owners and recycling companies would have to hold up production until a particular mesh or part could be ordered manufactured and delivered, resulting in costly down time and hugely inefficient working methods.

Approaching the issue from the perspective of the client, Harpscreen GB recognised the need to have parts in stock, so they could be ready to go at all times with the result that the end user could continue production uninterrupted.

Thanks to this unique selling point, Harpscreen GB is now the ‘go-to’ for clients in the UK and beyond who need a fast turnaround and who want to maximise their uptime.

But don’t just take our word for it…

Harry Hughes, mechanical maintenance manager at Torr Works, Aggregates South, commented about the ‘Harpscreen difference’ saying: “We have been working with Harpscreen for some time now and approached them about the possibility of some cost saving options and they were very accommodating, coming out during weekend shutdown to measure up meaning production was not affected; a real plus for a busy production plant. As a result of working with Harpscreen we have managed to save our spend, allowing more budget for screen media.”

Operations Director - Paul Blanchard, commented, “In the 18 years I have been with Harpscreen GB, our team’s dedication to transform not just a business but an entire industry has been amazing. “Enjoying the highs and lows of growing our turnover from £2m to £7.5m annually has been challenging and rewarding in equal measure. We have demonstrated that hard work and vision build leaders. We are number one in our field and ready to push on and conquer new markets in Europe, USA and Australia while standing proudly as a British manufacturer.”

A few current hot topics easily explained by Harpscreen GB illustrating the strength and depth of the team behind Harpscreen GB:

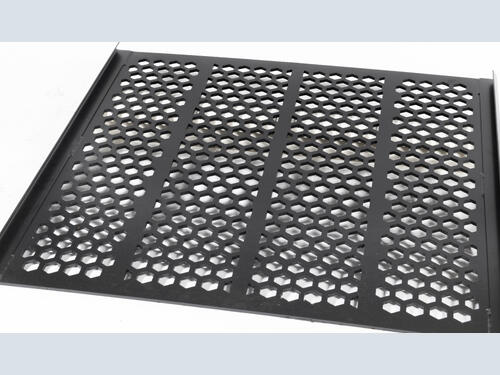

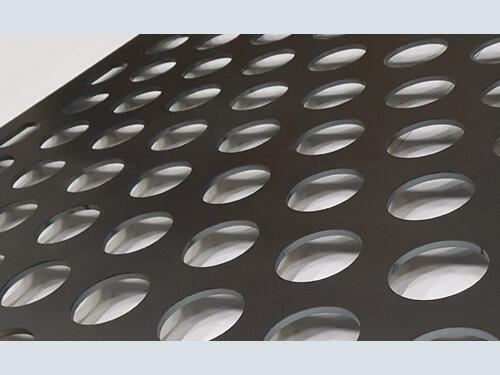

Maximizing efficiency in aggregate screening: The power of mild steel and Hardox® punched plate.

When it comes to screening aggregates in the construction, quarrying and recycling industries, the type of screening media and material they are made from can make all the difference in durability, performance, and cost-efficiency.

When producing punched plates for screening applications there are two stand out materials used mild steel and Hardox® steel.

Here’s why:

Mild Steel Punched Plate:

A more cost-effective solution

Mild steel is perfect for the applications with lower levels of abrasion or impact intensity and is most popular for its affordability. It is also more flexible than Hardox® material making it more manageable to roll/bend/fold when it comes to producing trommel screens.

Hardox® Punched Plate:

Durability and Wear Resistance

Hardox® stands out as a premium wear-resistant material and is ideal for high-impact and high abrasion conditions.

More suited to mobile/static incline screeners, Hardox® plates retain their strength and performance for a long time, reducing downtime, maintenance costs and improving overall operational efficiency.

Whether you are screening sand, gravel, or other aggregates, using the right material for your punched plate can enhance productivity, reduce downtime, and drive long-term savings.

Key benefits:

- Cost savings with mild steel

- Increased longevity and performance with Hardox®

- Optimized operational efficiency

- Reduced maintenance and downtime

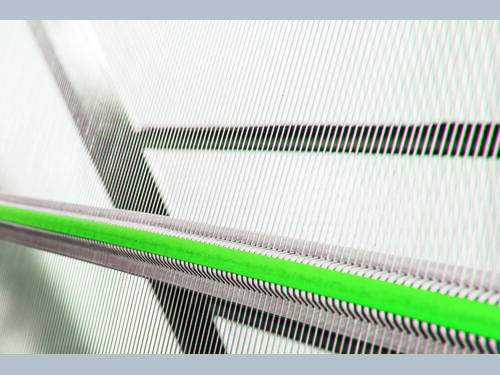

What Are Piano Wire Screens?

Piano Wire Screens are composed of long, thin, highly tensioned wires, made from high-tensile steel or stainless steel.

The wires are arranged vertically and held in place by plastic profiles, which sit on the camber bars inside the screen box.

The name comes from their resemblance to the strings of a piano — slim, taut, and capable of vibrating independently.

Piano wire screens are particularly beneficial in sand screening operations for several reasons:

Anti-Clogging Properties

Fine or damp sand often causes standard woven wire screens to clog or blind, drastically reducing throughput. The flexible wires in piano screens vibrate independently, shaking off material and keeping the screening surface clean.

High Screening Efficiency

Their open area is typically higher than conventional woven screens, allowing more sand to pass through and therefore increasing overall screening capacity.

Durability and Wear Resistance

Made from high-tensile or stainless-steel wire, these screens can withstand the abrasive nature of sand better than many other types of screening media offering a longer lifespan under tough conditions.

Customization

Piano wire screens can be manufactured with variable spacing and wire diameters to match specific screening requirements.

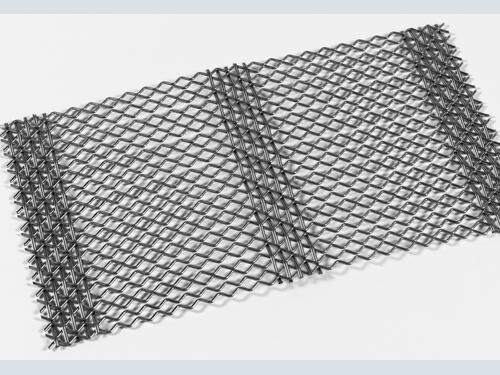

Harpscreen self-cleaning screening media

One of the most common challenges in aggregate screening is screening media blinding and clogging. Both of these issues can drastically reduce throughput, affect product quality, and increase downtime.

Harpscreen self-cleaning screening media, or ‘Flexis’ are designed to maximise screen performance but reducing material build up and minimising maintenance.

Unlike traditional woven wire, Harpscreen self-cleaning screens incorporate flexible wires that move independently under vibration. This movement allows the media to shed sticky, wet, or fine materials that would otherwise clog standard screens.

Our standard self-cleaning screens are made up of a combination of straight, rigid wires and zig-zag wires to create a triangular shaped pattern that prevents fines from settling to produce a more precise, clean product.

Our diamond type self-cleaning screens feature diamond-shaped openings making them highly effective when screening more difficult to screen materials.

Available in high-tensile and stainless-steel wire, both standard and diamond type can also be manufactured with polyurethane cross wires which further reduces the amount of buildup that may occur with wire cross wires.

Stand number - Central Hall - C30163 - CONEXPO-CON / AGG - Las Vegas NV March 3rd – 7th 2026