Page 108 - Hub 4 Magazine issue 53

P. 108

Recycling

DP Cold Planing venture down new roads in the recycling market

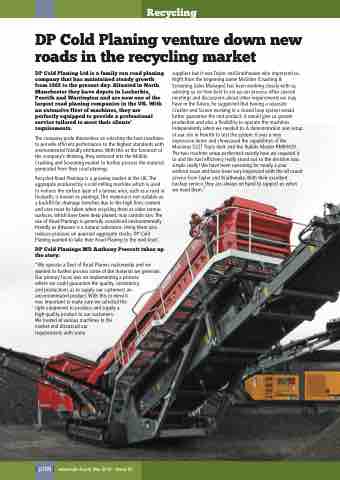

DP Cold Planing Ltd is a family run road planing company that has maintained steady growth from 1985 to the present day. Situated in North Manchester they have depots in Lockerbie, Penrith and Warrington and are now one of the largest road planing companies in the UK. With an extensive fleet of machines, they are perfectly equipped to provide a professional service tailored to meet their clients’ requirements.

The company pride themselves on selecting the best machines to provide efficient performance to the highest standards with environmental friendly attributes. With this at the foremost of the company’s thinking, they ventured into the Mobile Crushing and Screening market to further process the material generated from their road planings.

Recycled Road Planings is a growing market in the UK. The aggregate produced by a cold milling machine which is used to remove the surface layer of a tarmac area, such as a road or footpath, is known as planings. This material is not suitable as a backfill for drainage trenches due to the high fines content and care must be taken when recycling them as older tarmac surfaces, which have been deep planed, may contain tars. The use of Road Planings is generally considered environmentally friendly as Bitumen is a natural substance. Using them also reduces pressure on quarried aggregate stocks. DP Cold Planing wanted to take their Road Planing to the next level.

DP Cold Planings MD Anthony Prescott takes up the story:

“We operate a fleet of Road Planers nationwide and we wanted to further process some of the material we generate. Our primary focus was on implementing a process

where we could guarantee the quality, consistency

and productions as to supply our customers an uncontaminated product. With this in mind it

was important to make sure we selected the

right equipment to produce and supply a

high quality product to our customers.

We looked at various machines in the

market and discussed our

requirements with some

suppliers but it was Taylor and Braithwaite who impressed us. Right from the beginning Jaime McGlinn (Crushing & Screening Sales Manager) has been working closely with us, advising us on how best to set up our process. After several meetings and discussions about other requirements we may have in the future, he suggested that having a separate Crusher and Screen working in a closed loop system would better guarantee the end product. It would give us greater production and also a flexibility to operate the machines independently when we needed to. A demonstration was setup at our site in Penrith to test the system. It was a very impressive demo and showcased the capabilities of the Maximus 522T Triple deck and the Rubble Master RM90GO!. The two machine setup performed exactly how we required it to and the fuel efficiency really stood out so the decision was simple really! We have been operating for nearly a year without issue and have been very Impressed with the all round service from Taylor and Braithwaite. With their excellent backup service, they are always on hand to support us when we need them.”

| p108 |

www.hub-4.com Nov 2018 - Issue 53