Page 110 - Hub 4 Magazine issue 53

P. 110

Material

Handlers

B&M’s little

green powerhouse

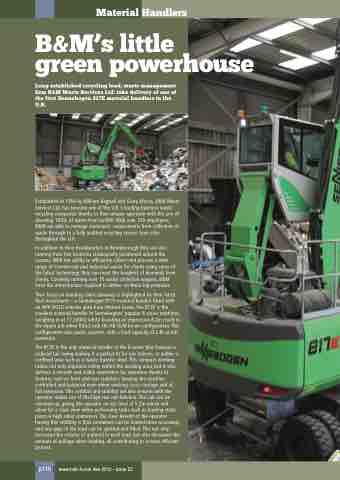

Long established recycling lead, waste management firm B&M Waste Services Ltd. take delivery of one of the first Sennebogen 817E material handlers in the U.K.

Established in 1954 by William Bagnall and Gerry Morris, B&M Waste Services Ltd. has become one of the U.K.’s leading business waste recycling companies thanks to their unique approach with the aim of diverting 100% of waste from landfill. With over 230 employees, B&M are able to manage customers’ requirements from collection of waste through to a fully audited recycling service from sites throughout the U.K.

In addition to their headquarters in Bromborough they are also running from five locations strategically positioned around the country. With the ability to efficiently collect and process a wide range of Commercial and Industrial waste for clients using some of the latest technology, they can meet the toughest of demands from clients. Currently running over 70 waste collection wagons, B&M have the infrastructure required to deliver on these big promises.

Their focus on meeting client demands is highlighted by their latest fleet investment – a Sennebogen 817E material handler fitted with an NPK DG16 selector grab from Molson Green. The 817E is the smallest material handler in Sennebogens’ popular 8 series machines, weighing in at 17,200Kg whilst boasting an impressive 8.2m reach to the dipper pin when fitted with the K8 ULM boom configuration. This configuration also packs a punch, with a load capacity of 2.8t at full extension.

The 817E is the only material handler in the 8 series that features a reduced tail swing making it a perfect fit for use indoors, or within a confined area such as a waste transfer shed. This compact working radius not only improves safety within the working area, but it also delivers a smooth and stable experience for operators thanks to features such as front and rear stablisers keeping the machine controlled and balanced even when working cross-carriage and at full extension. This comfort and stability are also present with the operator makes use of the high-rise cab function. The cab can be elevated up, giving the operator an eye level of 5.2m which will allow for a clear view when performing tasks such as loading static plant or high sided containers. The clear benefit of the operator having this visibility is that containers can be loaded more accurately and any gaps in the load can be spotted and filled. This not only increased the volume of material in each load, but also decreases the amount of spillage when loading, all contributing to a more efficient process.

| p110 |

www.hub-4.com Nov 2018 - Issue 53