Page 21 - HUB-4 Magazine Issue 85

P. 21

Aggregate

Washing & Screening

challenging sources. We can integrate density separation processes into the overall solution for coarse and fine materials allowing heavier contamination to be removed such as dense plastics, saturated organics, gypsum, and wood.

“For Allstone we integrated our density separation cyclone providing a consistent high-quality sand product. Additionally, the system can provide high levels of fines recovery to increase saleable products and reduce consumables in the effluent treatment circuit.”

Equipment supply:

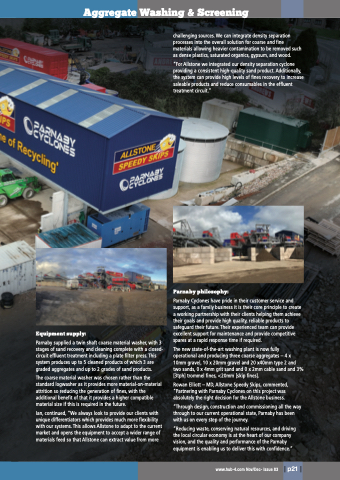

Parnaby supplied a twin shaft coarse material washer, with 3 stages of sand recovery and cleaning complete with a closed- circuit effluent treatment including a plate filter press. This system produces up to 5 cleaned products of which 3 are graded aggregates and up to 2 grades of sand products.

The coarse material washer was chosen rather than the standard logwasher as it provides more material-on-material attrition so reducing the generation of fines, with the additional benefit of that it provides a higher compatible material size if this is required in the future.

Ian, continued, “We always look to provide our clients with unique differentiators which provides much more flexibility with our systems. This allows Allstone to adapt to the current market and opens the equipment to accept a wider range of materials feed so that Allstone can extract value from more

Parnaby philosophy:

Parnaby Cyclones have pride in their customer service and support, as a family business it is their core principle to create a working partnership with their clients helping them achieve their goals and provide high quality, reliable products to safeguard their future. Their experienced team can provide excellent support for maintenance and provide competitive spares at a rapid response time if required.

The new state-of-the-art washing plant is now fully operational and producing three coarse aggregates – 4 x 10mm gravel, 10 x 20mm gravel and 20 x40mm type 2 and two sands, 0 x 4mm grit sand and 0 x 2mm cable sand and 3% [3tph] trommel fines, <20mm [skip fines].

Rowan Elliott – MD, Allstone Speedy Skips, commented, “Partnering with Parnaby Cyclones on this project was absolutely the right decision for the Allstone business.

“Through design, construction and commissioning all the way through to our current operational state, Parnaby has been with us on every step of the journey.

“Reducing waste, conserving natural resources, and driving the local circular economy is at the heart of our company vision, and the quality and performance of the Parnaby equipment is enabling us to deliver this with confidence.”

www.hub-4.com Nov/Dec- Issue 83

| p21 |